819

Views & Citations10

Likes & Shares

Temperature sensitivity of waxy crude oils makes it difficult to study their flow behaviour in the presence of water especially near their wax appearance temperatures (WAT). This mini-review provides an overview of the challenges faced by researchers in operating a multiphase flow facility while using a typical Malaysian waxy crude oil. The outcomes of applying a new technique for controlling of the mixture temperature are also highlighted. Since the waxy crude oil in two-phase flow is a relatively uncharted area of study, the results of this study can provide a platform for furthering research.

The presence of paraffinic waxes, regardless of their proportion, in all types of crude oils highlights the significance of any type of multiphase flow study with respect to these components [5]. Nevertheless, research works done on oil-water two-phase flows have mostly been restricted to the use of model oils (i.e., synthetic or mineral oils) rather than actual crude oils [6-8]. Although this practice is accepted as an attempt to improve the general knowledge on the subject, recent studies have shown that overly simplistic model oil cannot be a perfect representative of complex crude oils in terms of flow behavior. Therefore, as the first attempt, this research was aimed at studying the flow behavior of a typical Malaysian waxy crude oil in an

EXPERIMENTAL SETUP AND MEASUREMENTS

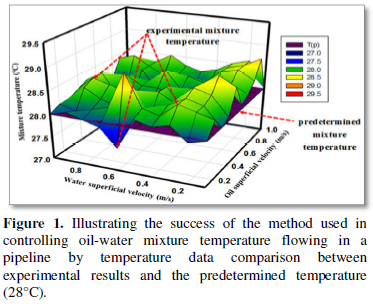

To accomplish this study, a flow test facility was designed, constructed, and commissioned at the Malaysia Petroleum Resources Corporation Institute for Oil and Gas (UTM-MPRC Institute for Oil and Gas), Universiti Technology Malaysia (UTM). The facility is capable of simulating single or two phase flow of oil and water in a horizontal pipe. It should be noted that, in this study, the focus is only on the concurrent flow of local tap water and a typical Malaysian waxy crude oil at three mixture temperatures (i.e., 26, 28 and 30°C) under various flow conditions. To facilitate the temperature control of the system, a method was also proposed and implemented to predict mixture temperatures prior to the experimental flow of the oil and water in the designed horizontal multiphase flow loop. To observe this method in action, mixture temperatures, pressure drops and liquid holdups were experimentally measured for mixture velocity ranging from 0.2 to 1.7 m/s in a carbon steel horizontal pipe. Accordingly, flow patterns were determined by considering a combination of visual observations, pressure drop interpretations and free water measurements. Moreover, water-in-oil emulsion samples of different water-cuts (10 to 70%) under three distinct rotational speeds (600, 900 and 1200 RPM) were prepared for thermal analysis. Upon the preparation of the samples, small specimens were collected for differential scanning calorimetry test to examine the effect of emulsified water droplets on accelerating the wax crystallization process above the WAT.

RESULTS AND DISCUSSION

Greater deviations became apparent at higher water volume fractions and rotational speeds, which resulted in the formation of a larger number of droplets. As a final analysis, it is not suggested to extend the obtained results of any liquid-liquid two-phase flow systems including model oils or non-waxy crude oils to those of waxy crude oils. Such comparisons are hardly plausible and further studies on waxy crude oils under two-phase flow conditions are still essential.

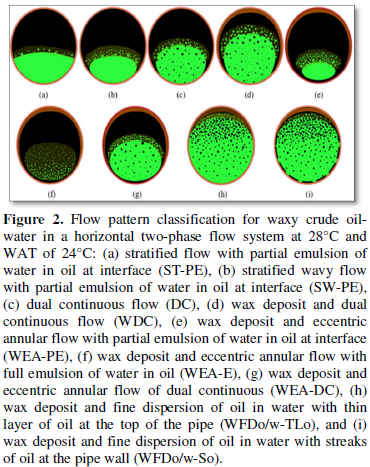

COMPARATIVE REMARKS ON THE FLOW PATTERNS

A comparison between the presented flow patterns and those obtained by preceding investigators is, by and large, difficult and intricate. This emanates from the extensive experimental variables involved in the perception and definition of the flow patterns, including fluid properties, implemented methods, operational conditions and inconsistent nomenclature and terminology. Despite all the mentioned impediments, the most similar classification found in the literature to this work is from the studies using crude oils rather than model oils such as the one proposed by Wang et al. [9] for heavy crude oil/water flows. In the studies pertinent to model oil/water flows [1,2,4]. The onset of entrainment and mixing of the phases at the interface have been evidenced upon the emergence of stratified wavy flows at relatively higher mixture velocities. However, all the flow patterns observed in this study, including stratified smooth flow, were accompanied with water-in-oil emulsions which are in line with the findings by Wang et al. [9]. Apart from this fact, the observed flow patterns in this study are more or less analogous to those defined by previous investigators, though not all of them can be found in a single previous study due to the differences in the conditions under which they occurred. Yet, there is an explicit diversity in the phase configuration and flow characteristic of annular flows observed in this study from the conventional annular flows found in the literature.

CONCLUSION

Based on the fact that paraffinic waxes are present in all types of crudes regardless of their proportion, it highlights the significance of this study which considered waxes in its two-phase flow research work. It can be deduced from the results that using the WAT of dried oil as the WAT of its emulsion are subject to substantial errors. If the possible thermal effects of the presence of water on the emulsion WAT are neglected, the consequence could be the unwanted deposition of wax crystals at temperatures greater than the WAT of that crude oil. This could threaten the success of flow assurance operations, especially for temperature-sensitive systems, such as the offshore pipeline transport of waxy crude oils.

- Al-Wahaibi T (2012) Pressure gradient correlation for oil-water separated flow in horizontal pipes Exp Thermal Fluid Sci 42: 196-203.

- Al-Wahaibi T, Smith M, Angeli P (2007) Effect of drag-reducing polymers on horizontal oil-water flows. J Pet Sci Eng 57: 334-346.

- Brauner N (2003) Liquid-liquid two-phase flow systems. In: Bertola V (Ed.) Modelling and Experimentation in Two-Phase Flow. Vienna: Springer. 450: 221-279.

- Elseth G (2001) An experimental study of oil/water flow in horizontal pipes. Norwegian University of Science and Technology, Norway.

- Manning, F, Thompson R (1995) Oilfield processing. Volume 2: Crude Oil. (1st edn) Tulsa, Oklahoma: Pennwell Publishing Company.

- Cai J, Li C, Tang X, Ayello F, Richter S, et al. (2012) Experimental study of water wetting in oil-water two phase flow-horizontal flow of model oil. Chem Eng Sci 73: 334-344.

- Kee KE, Richter S, Babic M, Nešić S (2014) Flow patterns and water wetting in oil-water two phase flows - A flow loop study. NACE International Conference Series, CORROSION 2014. 9-13 March. San Antonio, Texas, Paper No. 4068.

- Tan C, Li P, Dai W, Dong F (2015) Characterization of oil-water two-phase pipe flow with a combined conductivity/capacitance sensor and wavelet analysis. Chem Eng Sci 134: 153-168.

- Wang W, Gong J, Angeli P (2011) Investigation on heavy crude-water two phase flow and related flow characteristics.